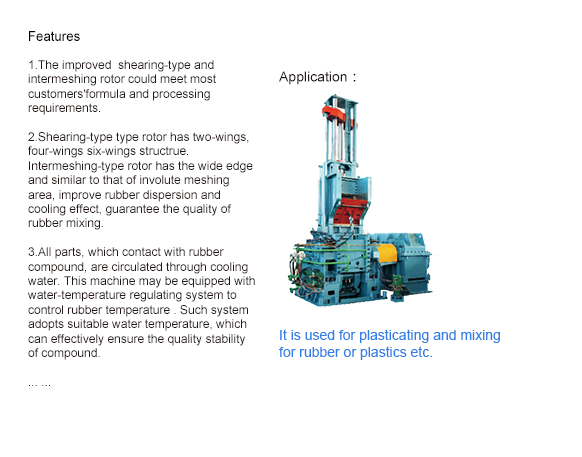

X(S)M Internal Mixer

X(S)M Internal Mixer

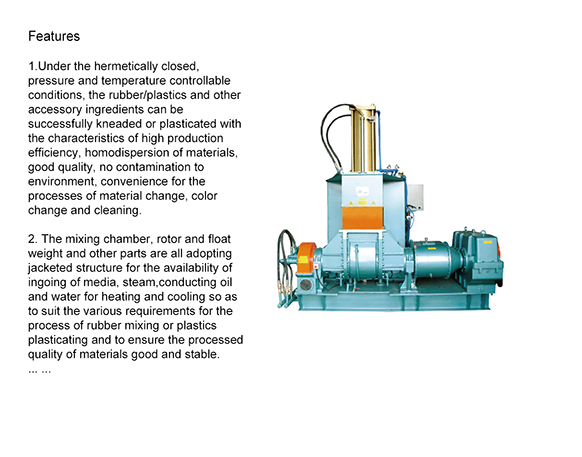

X(S)N rubber and plastics pressure Mixer (Kneader)

X(S)N rubber and plastics pressure Mixer (Kneader)

TPR pressure Mixer/EVA pressure mixer(Kneader)

TPR pressure Mixer/EVA pressure mixer(Kneader)

SNF series Rubber (Plastics) Pressure Mixer

SNF series Rubber (Plastics) Pressure Mixer

Kneader with hydraulic ram

Kneader with hydraulic ram

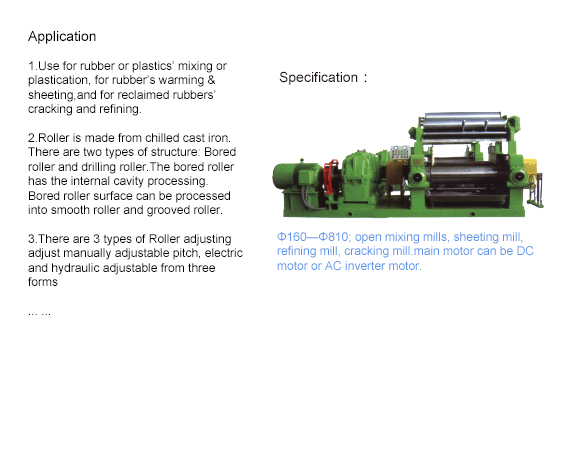

X(S)K series Open Mixing Mill

X(S)K series Open Mixing Mill

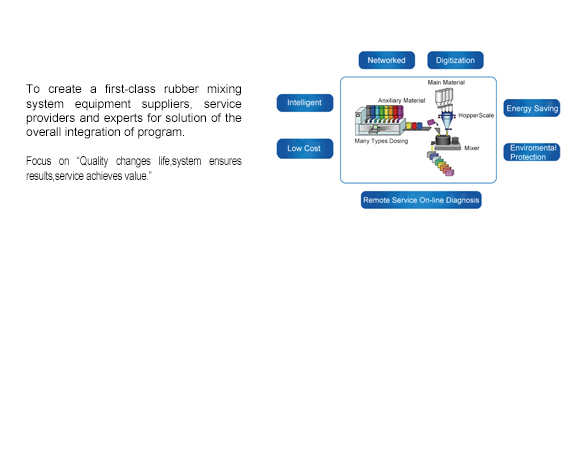

Auxiliary System

Auxiliary System

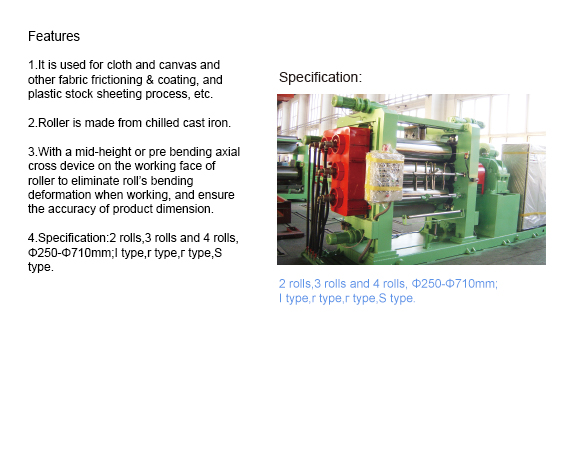

XY series rubber (plastics) Calender

XY series rubber (plastics) Calender

Cold-feed Extruder

Cold-feed Extruder

Twin-screw extruding and sheeting machinery

Twin-screw extruding and sheeting machinery

Bucket conveyor/ Rubber cutter machinery

Bucket conveyor/ Rubber cutter machinery

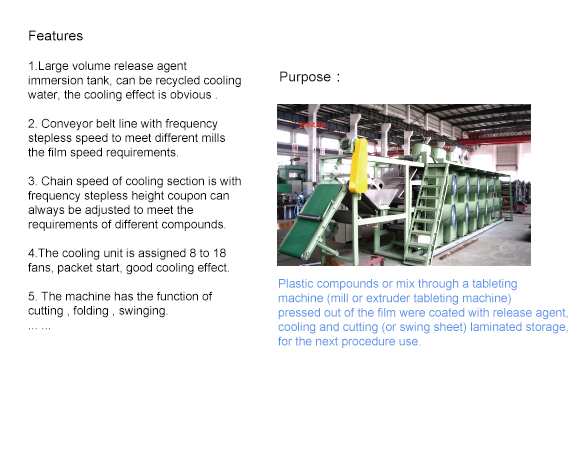

Batch-off cooling machinery

Batch-off cooling machinery

Processing Line

Processing Line

|